|

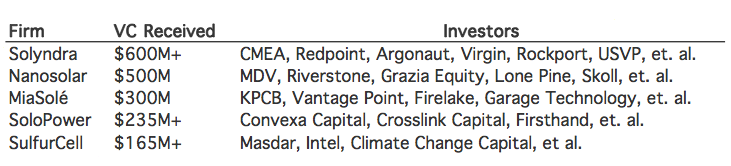

Sale of CIGS Solar Cell Panels Expected to Reach $1 Billion by 2013

Over $2.3 Billion has been invested by Venture Capital Firms in 35 different CIGS Solar Cell Technology companies. Of this amount, the top 5 firms, shown below have received $1.8 Billion.

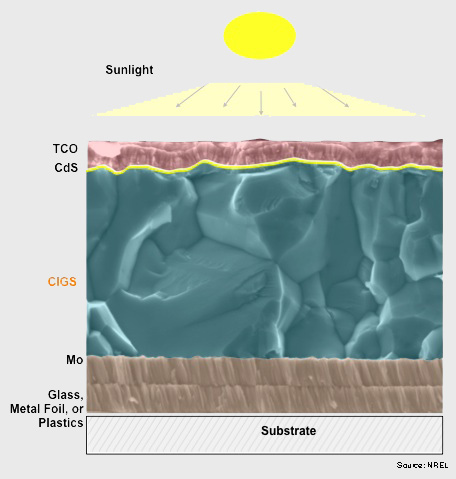

Note: CIGS is an abbreviation for solar cells made from Copper Indium Gallium Selenide (CIGS). With the phenomenal market success of First Solar, evidence of higher efficiency rates in the laboratory and using a material that does not contain toxic cadmium, one can imagine the investment appeal of CIGS solar cell technology. Unfortunately for the investors, while laboratory results have been very promising, mass producing panels using CIGS solar cell technology has proven to be extremely difficult. Its' manufacture and behavior has not yet been mastered as evidenced by the very few CIGS firms in true commercial production. Almost every CIGS firm has experienced schedule delays, personnel shake-ups, or massive re-working of processes and technological approaches, and none have been able to reach the high efficiency levels first proved possible in the laboratory. A few firms such as Wuerth Solar and Global Solar are currently shipping commercial CIGS product. Others such as Solyndra and Nanosolar boast of winning large purchase orders but true large-scale production at promised costs and efficiencies is not yet proven, and already some firms seem to be dropping out of the race. However, because of continuing interest from developers and solar installers, CIGS is still a viable solar cell technology to watch, and some of the companies, especially those backed by larger companies such as Q-Cells' subsidiary Solibro and Global Solar, which Solon has a stake in, will likely survive. In fact, at least one research companies are predicting that the sale of solar panels using CIGS solar cell technology will grow from $321 million in revenue in 2009 to around $1 billion by 2013, despite the fact that many of today's CIGS companies won't be there to see the turn around. GBI Research even came out with a report in June 2010 that predicts that CIGS solar cell technology will emerge as the major solar cell technology by 2020. The report provides key data, information and analysis on the current status and future outlook of Global Thin film industry. 99% of the light shining on a CIGS solar cell will be absorbed in the first micrometer of the material. Cells made from CIGS are usually heterojunction structures—structures in which the junction is formed between semiconductors having different bandgaps. The most common material for the top or window layer in CIS devices is cadmium sulfide (CdS), although zinc is sometimes added to improve transparency. Adding small amounts of gallium to the lower absorbing CIS layer boosts its bandgap from its normal 1.0 electron-volts (eV), which improves the voltage and therefore the efficiency of the device. This particular variation is commonly called a copper indium gallium diselenide or "CIGS" solar cell. Basically, a CIGS solar cell consists of the following parts:

The CIGS solar cell companies will all have similar products. The difference between them lay in how they produce those cells. While there are many companies trying to make CIGS solar cheaper than the incumbent technology of silicon solar cells, one of the gaping structural gaps in a CIGS builder's business plan is the lack of standard manufacturing tools. This means that every CIGS player has to be an equipment builder as well as a PV module and panel vendor. That's technically risky and a highly inefficient use of VC investor capital. Currently, the following methods are used to manufacture CIGS solar cells: 1. The most common vacuum-based process co-evaporates or co-sputters copper, gallium, and indium, then anneals the resulting film with a selenide vapor to form the final CIGS structure. An alternative is to directly co-evaporate copper, gallium, indium and selenium onto a heated substrate.Most CIGS solar cells are produced using a co-evaporation technique that involves vacuums and can be costly and time-consuming. The elements are heated and deposited on a surface in a vacuum 2. NanoSolar uses a non-vacuum-based alternative process that mixes the materials into a liquid then deposits nano-particles of the precursor materials on the substrate and then sinters them in situ. 3. Electroplating is another low cost alternative to apply the CIGS layer. SoloPower uses this method. 4. A UCLA team has created its copper-indium-diselenide solar cell without going through the vacuum evaporation process. Instead, they dissolve their material into a liquid, apply it to a surface and bake it. In solution form, their solar absorber layer -- the part made from the copper-indium-diselenide or CIGS materials and critical to the performance of the cell -- can be easily painted or coated onto a surface. "In our method, [an] advantage is our solution technology has the potential to be fabricated in a continuous roll-to-roll process," Hou said, which is an important cost breakthrough. 5. AQT uses a dry reactive sputtering process and is targeting a $.65 per Watt capital cost and $1.06 per Watt cell cost.

With record laboratory CIGS solar cell efficiency at just below 20% for several years, the new trend of CIGS research has shifted to investigation on lower-cost deposition methods that could be an alternative to expensive vacuum processes. Applied Quantum Technology (AQT) which raised only $4.75 million from undisclosed sources produced CIGS materials (in less than a year) with an NREL tested efficiency of greater than 10%. It has taken most of the other players several years to reach that efficiency milestone. SoloPower earlier this year said that it had achieved 11 percent efficiency for its panels, which is relatively good compared with other CIGS makers.Currently, non-vacuum efficiencies of 10%-15% have been achieved by many parties, such as ISET, Nanosolar and IBM – which is slightly higher than the efficiency rating of Cadmium Telluride panels produced by First Solar.

So far the promise of CIGS solar cell technology has been greater than the reality, but certain advantages of this technology are beginning to emerge, namely: 1. The active layer (CIGS) can be deposited in a polycrystalline form directly onto molybdenum coated glass sheets or steel bands. This uses less energy than growing large crystals, which is a necessary step in the manufacture of crystalline silicon solar cells. Also unlike crystalline silicon, these substrates can be flexible. 2. One environmental advantage of CIGS solar cell technologies have over Cadmium Telluride solar cell panels is that it uses a much lower level of cadmium, in the form of cadmium sulfide. In some designs, sometimes zinc is used instead of cadmium sulfide all together. 3. Like Cadmium Telluride panels, CIGS solar cell panels show a better resistance to heat than silicon based solar panels.

1. Like all thin film solar panels, CIGS panels are not as efficient as crystalline silicon solar cells, for which the record efficiency lies at 24.7%. They are however, the most efficient of the thin film technologies. 2. So far being able to produce solar panels at prices that can compete with polycrystalline or cadmium telluride panels has not been possible. There is growing concern by some parties, that the cost of fabricating the product makes it difficult to be competitive with current grid prices. It may take several more years to solve the manufacturing problems and bring the production costs in line with the other leading producers of solar panels.

Some industry observers believe 2010 was the "coming out" year for CIGS companies as a number of companies started selling substantial numbers of CIGS modules. To read the full article on our blog site click here. NREL verifies MiaSole's 15.7% CIGS Thin-Film Module Conversion Efficiencies. To read the full article click here. Click on the appropriate link to return to the top of this page about CIGS solar cell technology or to return to the previous section about Thin Film Technologies.

|