|

What Is Amorphous Silicon? Why is it so Interesting Now?

Amorphous silicon (a-Si) is the non-crystalline form of silicon. It is the most well developed of the thin film technologies having been on the market for more than 15 years. It is widely used in pocket calculators, but it also powers some private homes, buildings, and remote facilities. United Solar Systems Corp. (UniSolar) pioneered amorphous-silicon solar cells and remains a major maker today, as does Sharp and Sanyo.

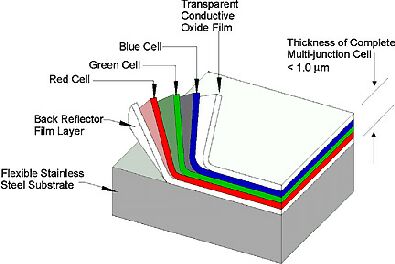

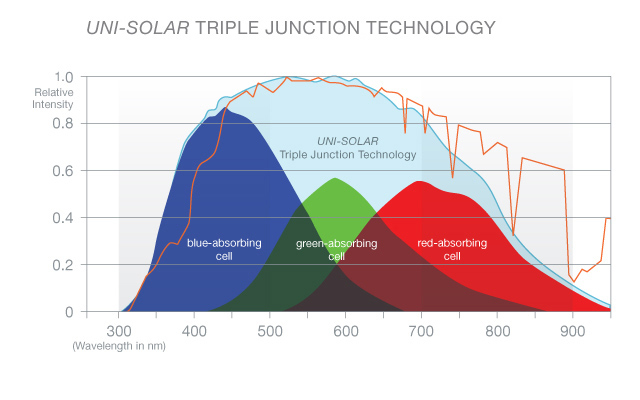

Amorphous silicon panels are formed by vapor-depositing a thin layer of silicon material – about 1 micrometer thick – on a substrate material such as glass or metal. Amorphous silicon can also be deposited at very low temperatures, as low as 75 degrees Celsius, which allows for deposition on plastic as well. In its simplest form, the cell structure has a single sequence of p-i-n layers. However, single layer cells suffer from significant degradation in their power output (in the range 15-35%) when exposed to the sun. The mechanism of degradation is called the Staebler-Wronski Effect, after its discoverers. Better stability requires the use of a thinner layers in order to increase the electric field strength across the material. However, this reduces light absorption, hence cell efficiency. This has led the industry to develop tandem and even triple layer devices that contain p-i-n cells stacked one on top of the other. One of the pioneers of developing solar cells using amorphous silicon is Uni-Solar. They use a triple layer system (see illustration below) that is optimized to capture light from the full solar spectrum).

As you can see from the illustration, the thickness of the solar cell is just 1 micron, or about 1/300th the size of mono-crystalline silicon solar cell.

While crystalline silicon achieves a yield of about 18 percent, amorphous solar cells’ yield remains at around 7 percent. The low efficiency rate is partly due to the Staebler-Wronski effect, which manifests itself in the first hours when the panels are exposed to sunlight, and results in a decrease in the energy yield of an amorphous silicon panel from 10 percent to around 7 percent. A German researcher from Delft University of Technology has demonstrated how to raise the energy output of amorphous silicon solar panels from around 7 percent to 9 percent. In his doctoral research, Gijs van Elzakker investigated adaptations in the production processes of amorphous silicon modules to increase the output without any additional costs using Silane Gas to reduce the Staebler-Wronski effect. This is just one approach being tried today. UniSolar's, laminate efficiency is currently at 8.2%; however, by late spring 2011, the company expects to be at 10% using their triple coating / triple junction technology. Banking on improvements in light-trapping, high-rate deposition, and a HybridNano technology, Uni-Solar expects to be able to push it's conversion efficiency to 12% by 2012 and believes it has the potential to reach 20+% for its product line.

The principal advantage of amorphous silicon solar cells is their lower manufacturing costs, which makes these cells very cost competitive. One of the main advantages of a-Si over crystalline silicon is that it is much more uniform over large areas. Since amorphous silicon is full of defects naturally, any other defects, such as impurities, do not affect the overall characteristics of the material too drastically. Amporphous silicon can be produced in a variety of shapes and sizes (e.g., round, square, hexagonal, or any other complex shape. This makes it an ideal technology to use in a variety of applications such as powering electronic calculators, solar wristwatches, garden lights, and to power car accessories. Small solar cells used in pocket calculators have been made with a-Si for many years. Unlike crystalline solar cells in which cells are cut apart and the recombined, amorphous silicon cells can be connected in series at the same time the cells are formed, making it is easy to create panels in a variety of voltages (e.g, for use in solar battery rechargers). The human eye is sensitive to light with wavelengths of 400 nm to 700 nm. Since amorphous silicon solar cells are sensitive to light with essentially the same wavelengths, this means that in addition to be used as solar cells they can also be used as light sensors (e.g., outdoor sensor lights, etc).

Some amorphous solar panels also come with shade-resistant technology or multiple circuits within the cells, so that if an entire row of cells is subject to complete shading, the circuit won't be completely broken and some output can still be gained. This is especially useful when installing solar panels on a boat. The development process of a-Si solar panels also renders them much less susceptible to breakage during transport or installation. This can help reduce the risk of damaging your significant investment in a photovoltaic system. Another principal advantage of this type of technology is greater resistance to heat. According to a four year NREL study – it was observed that amorphous silicon PV modules experience higher results as temperatures increase.

As mentioned previously, these panels have a lower efficiency than mono-crystalline solar cells, or even poly-crystalline solar cells. Attempts to increase the efficiency, such as building multi-layer cells or alloying with germanium to reduce its band gap and further improve light absorption all have an added complexity. Namely, the processes are more complex and process yields are likely to be lower and costs are likely to be higher as a result – thus reducing the cost advantage of this type of solar cell. The expected lifetime of amorphous cells is shorter than the lifetime of crystalline cells, although how much shorter is difficult to determine, especially as the technology continues to evolve. From reading through the literature, it appears that the expected life is still in the order of 25 years or so. For example, Uni-Solar offers the following performance guarantee on their 144 Wp panels: 92% at 10 years, 84% at 20 years , 80% at 25 year (of minimum power).

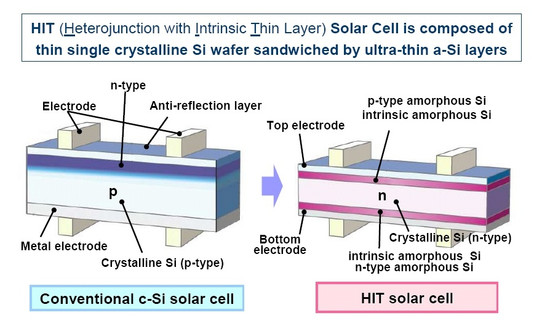

Sanyo has developed a hybrid solar cell by applying coatings of amorphous silicon onto a mono-crystalline solar cell (see accompanying diagram). They call this a HIT Solar Cell, and it has a 20.2% efficiency rating. According to IMS Research, Sanyo ranked number 10 in terms of MW of solar panels produced in the first quarter of 2010, due in large part to the popularity of its hybrid solar cell technology.

Besides the high efficiency rating, these cells take advantage of the high performance of amorphous silicon at higher temperatures (above 25˚ C) with the result that Sanyo claims the cells produce about 10% more electricity as temperatures rise than mono-crystalline silicon cells – making them worth considering if you are in a location where temperatures frequently exceed 25˚ C. (the operating temperatures range from –20˚C to 46˚C). Note: While most panel manufacturers specify that panel performance will range from –5% / +5% … Sanyo guarantees 100% performance (i.e., -0%/+10%) at time of delivery.

1.2 GW Solar Panel Factory to be Built in Siberia To find more valuable information or advice about the material covered in this post or about any other related or specific subject - use our built-in / Google Powered site searching tool below. Just type in a few key words or phrases to search this website, our solar news and health blogs for related articles. More than 600 artlicles have been published to date.  Custom Search Click on the appropriate link to return to the top of this page about amorphous silicon or to return to the previous section about Thin Film technologies in general.

|