|

Integrated Photovoltaics – A New Future for Silicon Solar Cells?

Integrated photovoltaics in the form of flexible plastic PV sheets and strips opens up the possibilities for many new applications. However, up until now – the efficiency of such products has been about 1/2 of that generated from crystalline silicon based PV cells. Now, CalTech professor California Institute of Technology physics professor Harry Atwater and his team of researchers has demonstrated it is possible to produce high efficiency solar cells using just a fraction of the silicon used in a traditional crystalline silicon cell, which are stiff and brittle.

"Our technology uses 50-100 times less silicon," he said, "in the form of a sparse array of wires. And that sparse array of wires has exactly the same light absorption and electricity-collection properties as the conventional silicon wafer cell."

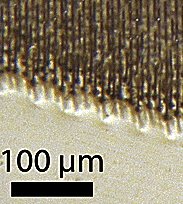

The tiny silicon wires stick up from the base, or substrate, looking something like a microscopic hairbrush. And because the key component of solar cells is an expensive, highly purified form of silicon, there's a real economic benefit to this design. So what that means is, in terms of cost of producing these type of integrated photovoltaics, is that you can only need 1% to 2% of the amount of silicon. Since silicon cost represents about 2/3rd of the cost to produce a crystalline silicon solar cell – the savings in the amount of silicon we require with this technology is potentially very significant.

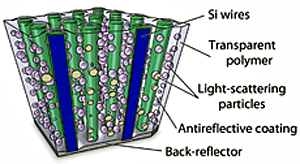

Since silicon is what converts light into electricity, you might think using so much less silicon would reduce the electrical output, but Atwater says that's not the case.

"The light comes in and is both directly absorbed by the wires, and some of the light bounces around in between the wires. The bouncing around or multiple scattering in between the wires results in dramatically enhanced absorption," Atwater explained. "In fact, the absorption enhancement that we see is in the range of 20 to 50 times the single-pass absorbance."

Atwater and his colleagues have made prototypes of the design in the lab, and the product doesn't look like the typical solar panels you might see on top of a building. "What we do with our wire arrays is grow them on a supporting substrate, and we peel them off inside a plastic sheet, so that the material has exactly the optical and electrical properties of a silicon wafer, but instead it basically has the mechanical properties of a flexible plastic sheet." That flexibility opens the door to potential new applications, such as what Atwater calls "integrated photovoltaics." For example, the solar cell could be built into roofing material, saving money on installation. One of the things that's interesting about these flexible and thin sheets is that they can be curved, so you could imagine putting them in unconventional forms, like on the surface of a vehicle, a boat, a pole or any type of non-flat surface. The Caltech professor says he's optimistic about commercializing his new solar cell design because the manufacturing process should not require development of any new technologies. And he stresses that it should reduce the cost of generating power from the sun. "The wonderful thing about solar energy is that it's accessible and available everywhere in the world, from the cloudiest place in northern Europe to the sunniest place in north-central Africa to the Outback of Australia to South Asia. And in fact [the use of solar energy is] growing worldwide for that reason." A more detailed of Harry Atwater's description of his new design for integrated photovoltaics using silicon wire array based solar cells is published in the journal Nature Materials. lick on the appropriate link to return to the top of this page about Integrated Photovoltaics or to return to the previous section and read more about current Solar Research.

|